Raw Material

ADC12 that has high copper percentage, in simple words it means, exceptional durability and longevity. ADC 12 increases the resistance of a material. Both cast and wrought aluminum-copper alloys respond to solution heat treatment and subsequent aging with an increase decrease in elongation.

Raw material specifications

- Lightweight and structural material

- Resistance to corrosion

- Endures high temperatures

| S.no |

Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| 1 |

Bought Out Parts (BOP) |

Main jet |

Inhouse |

Outsource |

Inhouse manufacturing ensures better quality control on produced parts |

| Throttle valve |

Inhouse |

Outsource |

| Jet needle |

Inhouse |

Outsource |

| 2 |

Raw material |

Outer body |

High grade ADC12 with copper content of 1.65%/High grade Zinc |

Substandard ADC12 with copper content of 0.5-0.8% which is below international standards |

1)Increased wear resistance

2) Long term dimensional stability |

| JBOP |

Brass alloy |

Alloy mix |

1) Reduce wear and tear |

Composition of ADC-12

| Metal |

Si |

Fe |

Cu |

Mn |

Mg |

Ni |

Zn |

Sn |

Al |

| % |

9.6~12 |

1.3 max |

1.5~3.5 |

0.5 max |

0.3 max |

0.5 max |

1 max |

0.3 max |

Balance |

Another most important raw material used is Zinc. Zinc alloy used for making carburetor is known as Zamak 3. It is the first choice when considering zinc for die casting for several reasons.

- Excellent balance of desirable physical and mechanical properties.

- Superb castability and long-term dimensional stability.

- Excellent finishing characteristics for plating, painting, and chromate treatments.

- Achieve high levels of accuracy.

- Exhibit increased wear resistance.

Composition of Zamak 3:

| Metal |

Al |

CU |

Mg |

Fe |

Pb |

Cd |

Sn |

Zn |

| % |

3.5~4.3 |

0.25 |

0.02~0.05 |

0.1 max |

0.005 max |

0.004 max |

0.003max |

Balance |

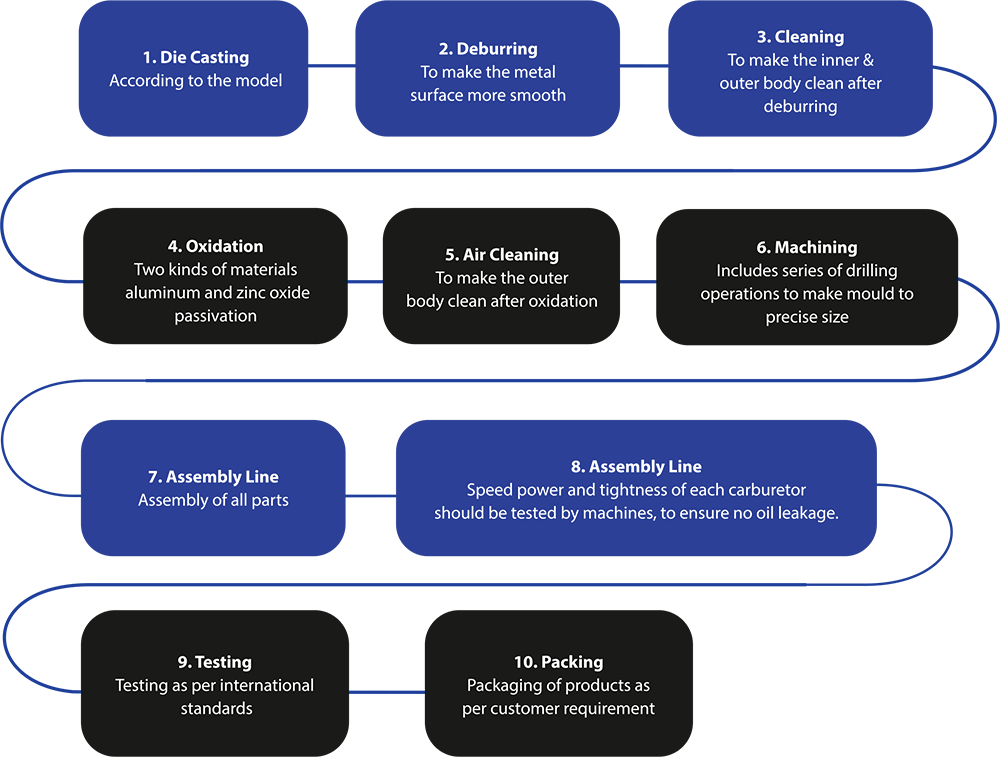

Manufacturing

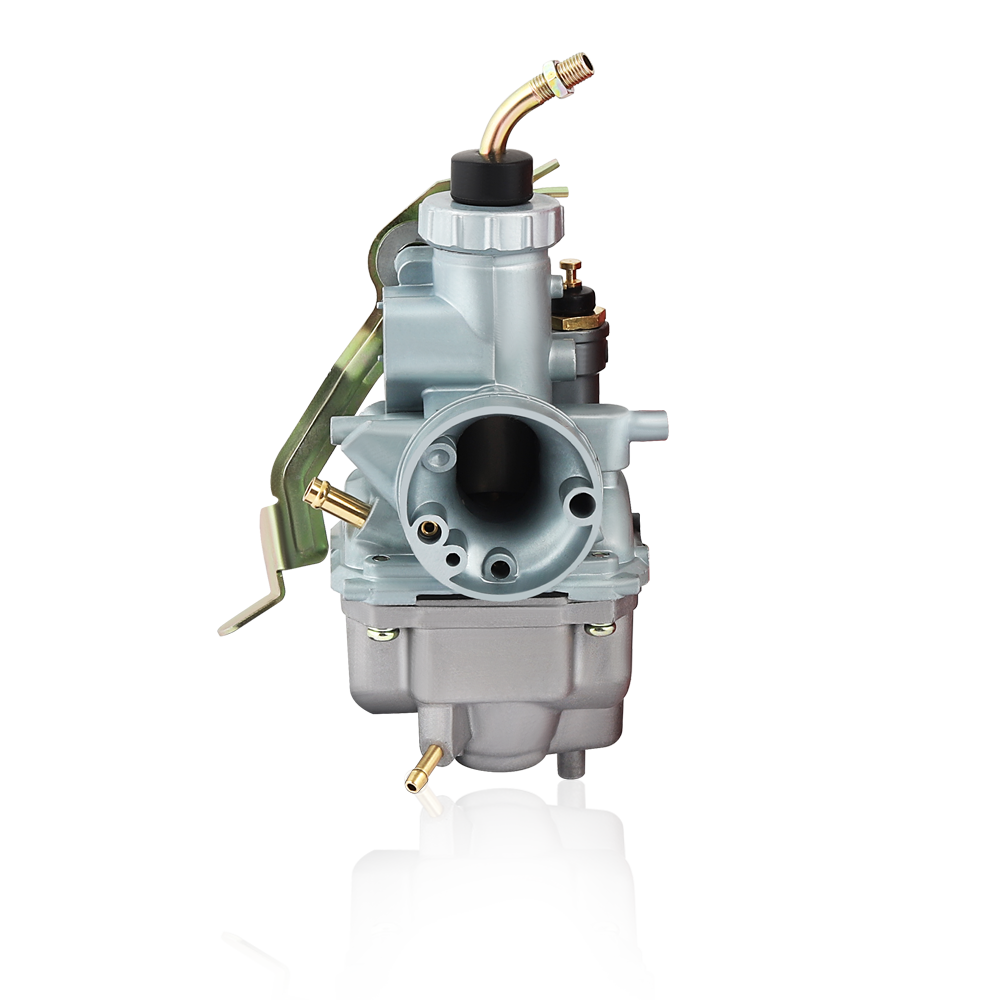

Our carburetor is designed to mix just the right amount of fuel with air so that the engine runs properly. The ratio should not be more than 20:1 and not less than 8:1. The ideal ratio is 15:1. If there is not enough fuel mixed with the air, the engine ‘runs lean’ and either will not run or potentially damage the engine. If there is too much fuel mixed with air, the engine ‘runs rich’ and either will not run or runs very smoky. We attain just the perfect level. Hence, we focus on the manufacturing process to avoid engine problems.

<

| S.no |

Description |

| 1 |

Rubber Cap |

| 2 |

Cable Adjuster |

| 3 |

Locknut, Cable Adjut. |

| 4 |

Mixing Chamber Top |

| 5 |

Spring, Throttle valve |

| 6 |

Seat Plate, spring |

| 7 |

E-ring, Jet Needle |

| 8 |

Throttle value 1.5 |

| 9 |

Starter plunger assembly |

| 11-16 |

N/A |

| 17 |

Air screw |

| 18 |

O-Ring, Air Screw |

| 19 |

Sprint, Air screw |

| 20 |

Idle Adj. Screw |

| 21 |

O-Ring, Idle Ajd. Screw |

| 22 |

Spring, Idle Ajd. Screw |

| 23 |

3MM ID vent Hose |

| 24 |

Pilot Jet |

| 25 |

Main Jet ring |

| 26 |

Needle jet 0-0 332/td> |

| 27 |

Large hex main jet |

| 28 |

Washer, Needle valve seat |

| 29 |

Needle valve jet (2.5) |

| 30 |

Float |

| 31 |

Float pin |

| 32 |

Float bowl gasket |

| 33 |

Float bowl |

| 34 |

O-Ring drain plug |

| 35 |

Drain plug |

| 36 |

Screw 4 X 16mm, Float bowl |

| 37 |

Top cap gasket (Not shown) |

| S.no. |

Parameter |

Details |

At RITSUKA |

Chinese Product |

RITSUKA Advantage |

| 1 |

Manufacturing |

Die casting |

Inhouse |

Outsourced |

Inhouse manufacturing ensures better quality control on produced parts |

| Child part |

Mostly In house |

Outsourced |

Stringent control over child part |

| Assembly |

In house |

In house |

Quality product |

Testing

We give emphasis on perfection and timely delivery. Every piece is manufactured to attain highest quality owing to our many checks and testsat every step.

Performance Test

Performance of 100% of the production lot is checked

| S.no |

Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| 1 |

Testing Standards |

Performance Test |

Inhouse |

Requires engine to perform the test |

All the tests are performed as per GB standard to ensure defect free product |

Material Test

| S.no |

Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| 1 |

Testing Standards |

Performance test |

Inhouse |

Requires engine to perform the test. |

All the tests are performed as per GB standard to ensure defect free product |

Leakage test

Each carburetor is tested to check the oil leakage.

| S.no |

Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| 1 |

Testing Standards |

Oil test |

Inhouse |

Partial |

All the tests are performed as per GB standard to ensure defect free product |