Raw Material

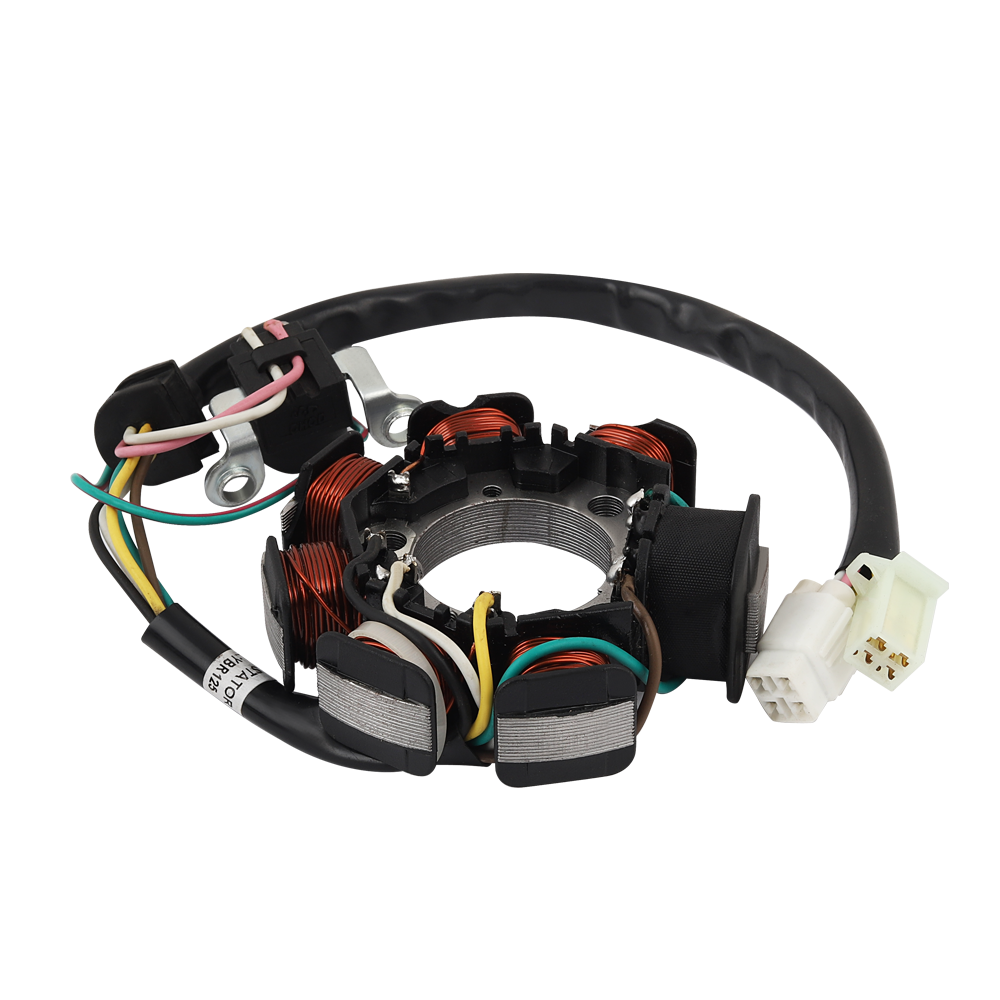

We use silicon steel for high magnetic flux generation, copper winding wires for high current generation and nylon PA66 lamination for safety in high rotation. Our streamlined production processes and adequate production lead time allows us to deliver unmatched quality along with a strong hold over the timely delivery, leading to utmost customer satisfaction at every given point.

| Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| BOP |

Frame |

Magnetic Iron |

Normal Iron |

High magnetic flux generation |

| Winding |

0.8 MM Copper |

0.75 MM Copper |

Required current generation |

| Lamination |

Nylon PA66 |

NA |

Provide safety in high speed rotation |

| Wiring |

0.75 MM wire |

Non Std |

Safety at high temperature and high current flow |

| Wire covering |

Fresh PVC |

Recycled PVC |

Safety at high temperature and high current flow |

| Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| Raw material |

Copper |

Chinese |

Chinese |

– |

| Sealant |

Fixed Chinese vendor |

Any local vendor |

Same standard quality in every lot |

| Wire |

Fixed Chinese vendor |

Any local vendor |

Same standard quality in every lot |

| Sheet Metal |

Fixed Chinese vendor |

Any local vendor |

Same standard quality in every lot |

Manufacturing

We believe in controlling manufacturing process at the maximum. We have a manufacturing capacity of churning out 200 thousand units of stators a month. Not just a mere quantity, we manufacture these sets for a wide range of models and our spare parts find themselves complementing the top global brands of motorcycles.

| Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| Manufacturing as per GB standard |

Frame Machining |

CNC machining to maintain correct co-centricity and outer |

Lathe machining to maintain correct co-centricity and outer |

CNC machine having less variation as compare to Lathe |

| Copper winding |

Electrical programmed machine |

Manual hand operation |

Machine will maintain same winding in every pcs, which ensure correct current generation |

| Varnishing |

Electrical programmed machine |

NA |

Give safety in high temperature |

| Soldering |

Hand made |

Hand Made |

|

Testing

Each of our carefully manufactured stators are further tested on international standards. We are passionate about creating the spare parts in the most brilliant way possible and our 100% quality inspection of products during production ensures quality product.

| Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| Testing Standard |

Incoming Quality Inspection |

100% inspection of incoming raw material |

No testing |

This ensure the incoming parts is within tolerance limit |

| In process |

100% quality check of metal frame to check the dimension and shape |

No quality check, since it requires extra manpower/extra cost |

This ensures that produced parts are within tolerance limit |

| In process |

100% quality check of winding by testing Machine to check the required round of copper wire |

No quality check, since it requires extra manpower/extra cost |

This ensures that produced parts are within tolerance |

| In process |

100% testing of current generation at test bench |

Check only at sample basis |

Defect free product to customer. |

| Final inspection |

40-50 hours continuous running |

No, as it requires time |

Defect free product to customer. |

Short winding test

This test is performed to check the short winding.

| Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| Testing Standard |

Short Circuit Test |

To ensure Short Winding |

No testing |

- Give safety in high temperature

|

Lamination testing

This test is performed to check the Lamination.

| Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| Testing Standard |

Lamination Testing |

To check the Lamination |

No testing |

- To ensure the safety in high temperature and current flow.

|

Final performance running testing

This test is performed to check the life of stator.

| Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| Testing Standard |

Final running testing |

To check the performance life of Stator |

Sample Basis |

- Best product to client

|