Raw Material

Our pedals are manufactured of high-grade steel –Q235.

| S.no. |

Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| 1 |

Raw material |

Steel |

High grade Q235 |

Substandard grade steel |

1)Increased wear resistance

2) Long term dimensional stability |

| RITSUKA Advantage |

% |

Test Method |

| Carbon |

0.131 |

ASTM E-415-2014 |

| Silicon |

0.1404 |

–do– |

| Manganese |

0.400 |

–do– |

| Sulphur |

0.022 |

–do– |

| Phosphorus |

0.0180 |

SPO/CHE/00-LAS |

| Chromium |

0.048 |

ASTM E-415-=2014 |

| Molybdenum |

<0.01 |

SPO/CHE/00-LAS |

| Nickel |

<0.020 |

–do– |

| Aluminum |

<0.017 |

–do– |

| Copper |

<0.021 |

–do– |

| Niobium |

<0.008 |

–do– |

| Cobalt |

<0.008 |

–do– |

| Nitrogen |

<0.006 |

ASTM E-415-=2014 |

| Boron |

<0.001 |

SPO/CHE/00-LAS |

| Lead |

<0.001 |

–do– |

| Vanadium |

<0.005 |

–do– |

| Tungsten |

<0.008 |

–do– |

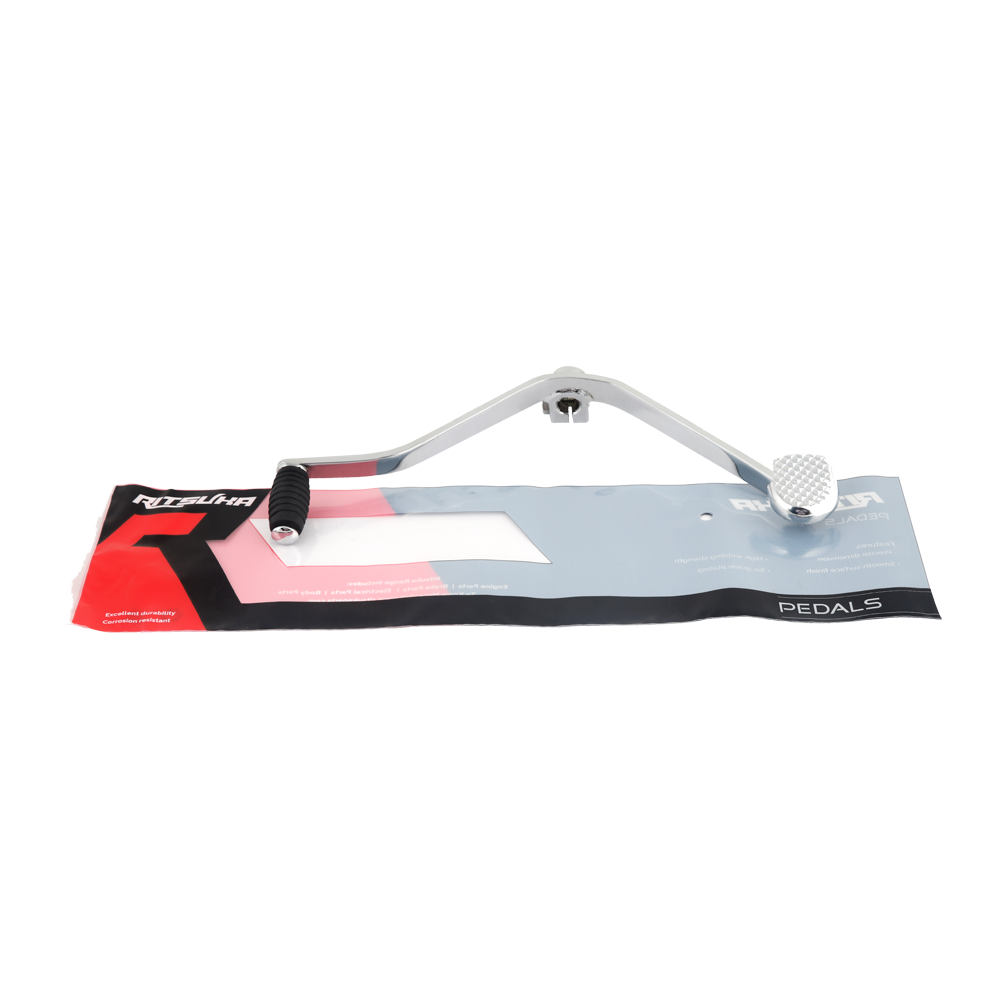

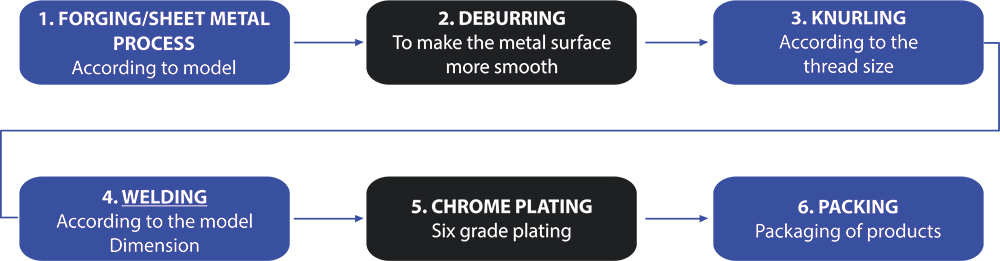

Manufacturing

We manufacture 200 thousand units of pedals a month. Our streamlined production processes and adequateproduction lead time allows us to deliver unmatched quality along with a strong hold over the timely delivery, leading to utmost customer satisfaction at every given point. We believe in transparency in our approach and hencewe have a warehouse web portal for customers to check the status of the goods.

| S.no |

Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| 1 |

Manufacturing as per GB standard |

Forging |

Inhouse forging with controlled parameters |

Outsourced |

Inhouse manufacturing ensures better quality control on produced parts |

| Sheet metal process |

Inhouse press shop with all the die produced inhouse |

Outsourced |

Inhouse manufacturing ensures better quality control on produced parts |

| Plating |

6-grade plating with inhouse facility |

4-grade plating |

Advantages of 6 grade plating:

1) Smooth finish

2) Avoid rust

3) Better aesthetics. |

| Welding |

Inhouse welding |

Inhouse welding |

|

Testing

Each of our part is carefully manufactured and tested as per international standards. Our 100% quality inspection of products during production ensures quality product.

| Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| Testing Standard |

Incoming Quality Inspection |

100% inspection of incoming raw material |

No testing |

This ensure the incoming parts is within tolerance limit |

| In process |

100% quality check at different processes to check the dimension and shape |

No quality check, since it requires extra manpower/extra cost |

This ensure the produced parts is within tolerance limit |

| Final inspection |

All the products are checked before dispatch to ensure good quality |

No quality check, since it requires extra manpower/extra cost |

Defect free product to customer. |

Salt Spray Test

This test is performed to check the corrosion resistance.

| Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| Testing Standard |

Salt spray test |

To check the corrosion resistance |

No testing |

1)Better quality assurance

2) Corrosion resistant |

Welding Strength Test

This test is performed to check the strength of weld parts.

| Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| Testing Standard |

Welding strength test |

To check the strength of weld parts |

No testing |

Better quality product |

Chrome Plating Test

This test is performed to check the Chrome plating thickness.

| Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| Testing Standard |

Chrome plating test |

To check the thickness of chrome plating |

No testing |

1) Smooth finish

2) reduce the risk of rust |