Manufacturing

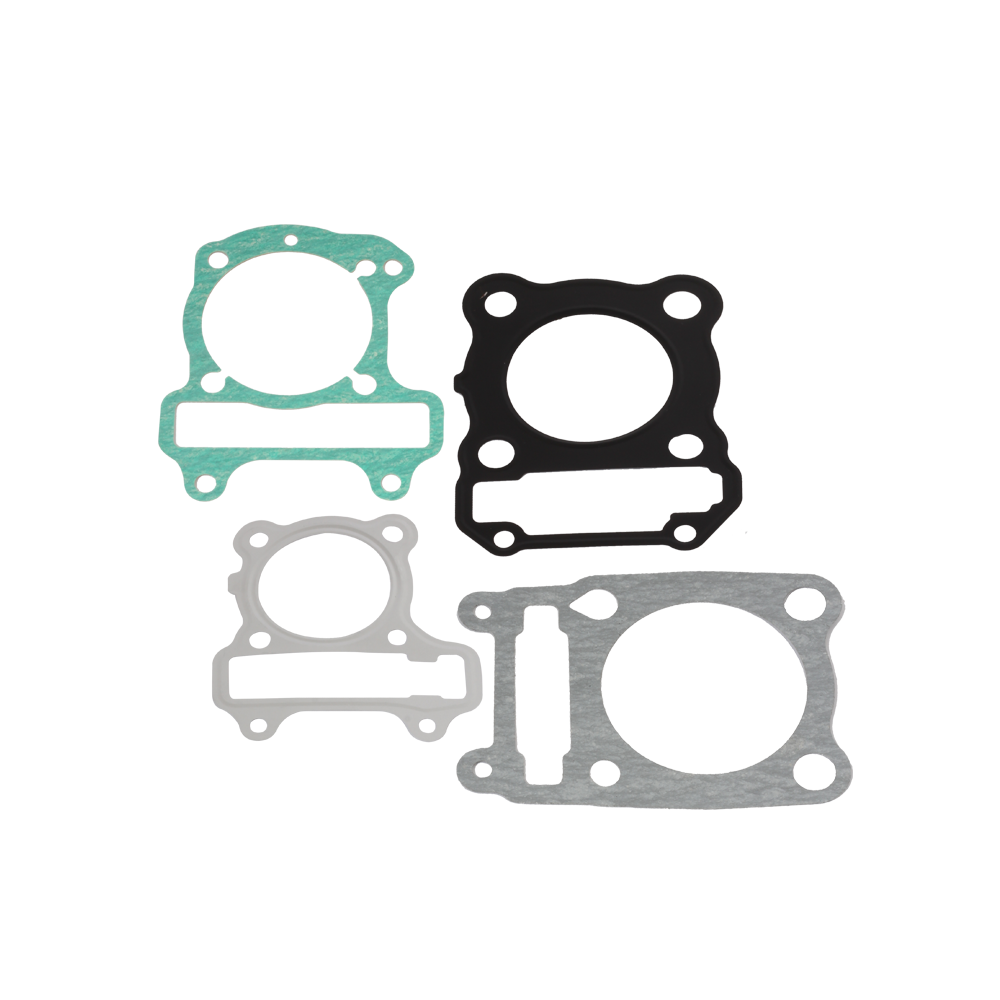

Our gaskets are manufactured of high grade –FKM, EPDM, NBR, steel and mix compound of asbestos and rubber.

| Parameter |

Details |

At RITSUKA |

Chinese Product |

RITSUKA Advantage |

| Manufacturing as per GB standard |

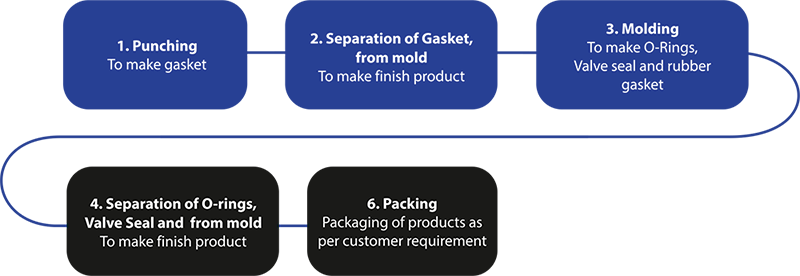

Punching |

Semi-Automatic 200 Metric ton punching Machine |

Hand operated less weight punching machine |

Flash free perfect profile of Gasket |

| Separation of Gasket |

Manual |

Manual |

– |

| Molding of Valve Seal |

Semi-Automatic temperature controlled Machine |

Local Machine |

Air bubble free molding |

| Packing as per model and requirement |

Manual |

Manual |

– |

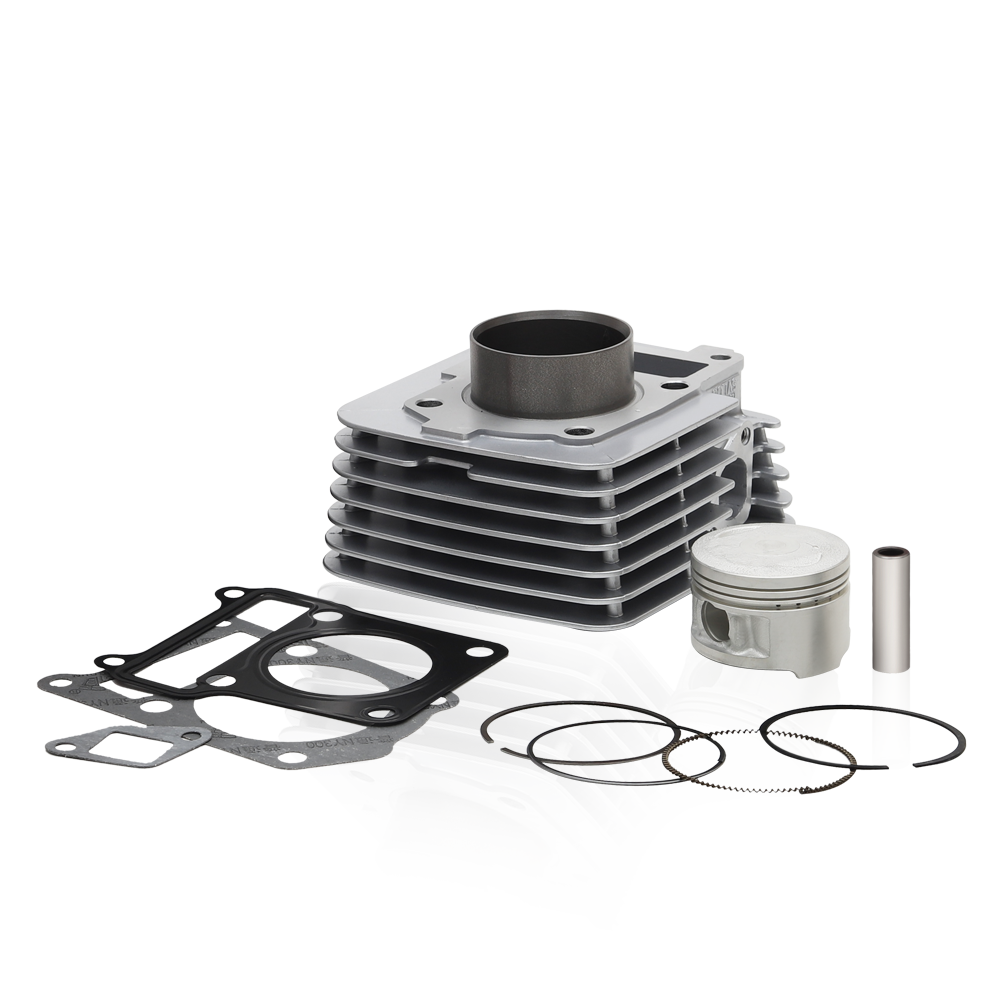

We have a capacity of manufacturing 200 thousand units of Gaskets a month. Not just a mere quantity, we manufacture for a wide range of models and our product complements top global brands of motorcycles.

Our team of experts adheres to the highest standards of quality and safety to deliver the best. We invest in high-level equipment enables control on manufacturing processes, which assures good quality level.

Testing

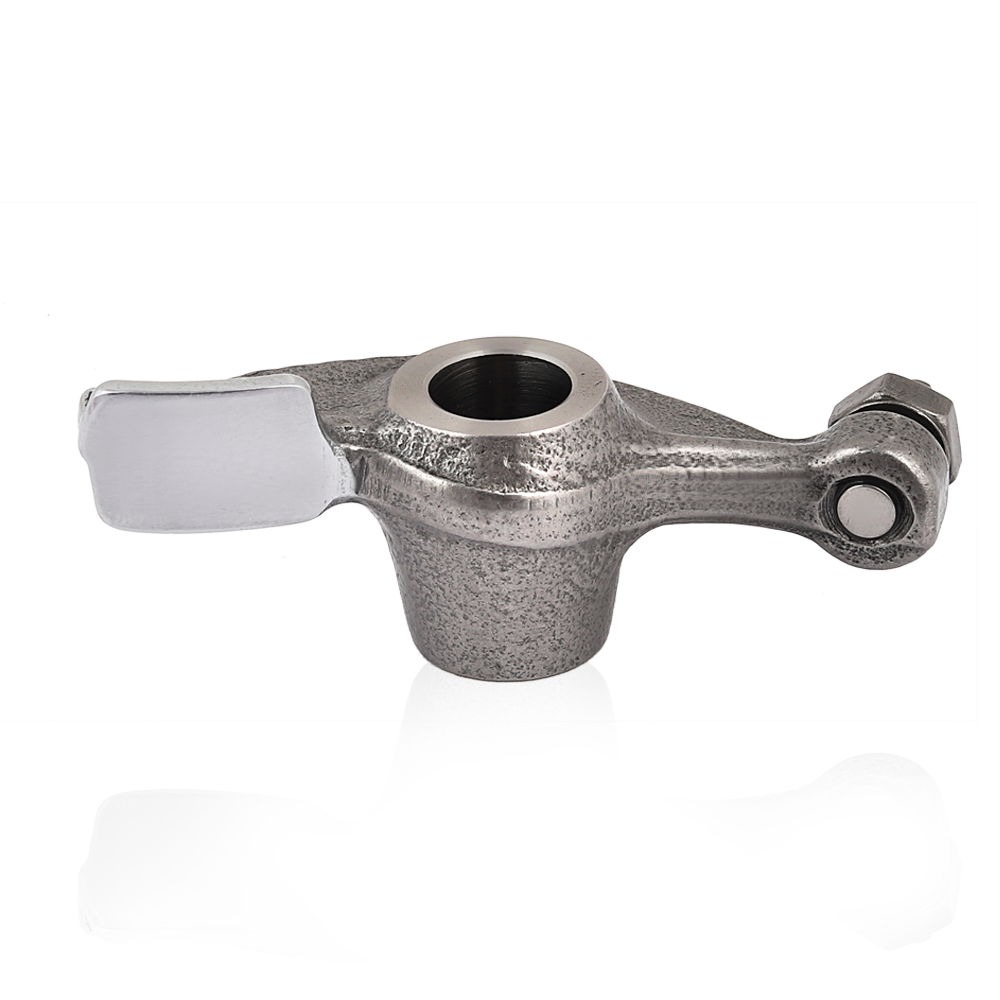

We manufacture each part with utmost passion and care. Our products go through a variety of tests before coming to the markets.

| Parameter |

Details |

At Rituska |

Chinese Product |

RITSUKA Advantage |

| Testing Standarard |

Incoming Quality Inspection |

100% inspection of incoming raw material |

Not testing |

This ensure the incoming part is within tolerance limit |

| Raw Material Test report |

Incoming material test report with every lot |

NA |

This ensure the default free raw material |

| Hardness testing |

Shore A Hardness testers hardness should between 40 to 90 |

No quality check, since it requires extra manpower/extra cost |

100% ensure of correct goods |

| Heat Testing |

Product should not deform at 300 degree Celsius |

No quality check, since it requires extra manpower/exctra cost |

Defect free product to customer. |

| 100% Final Quality Inspection |

Visual Final Checking |

Visual Final Checking |

Defect free product to customer |