Raw Material

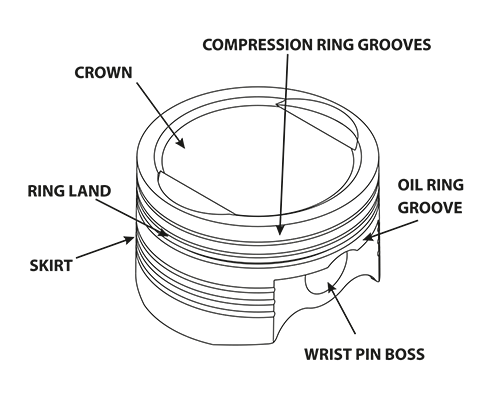

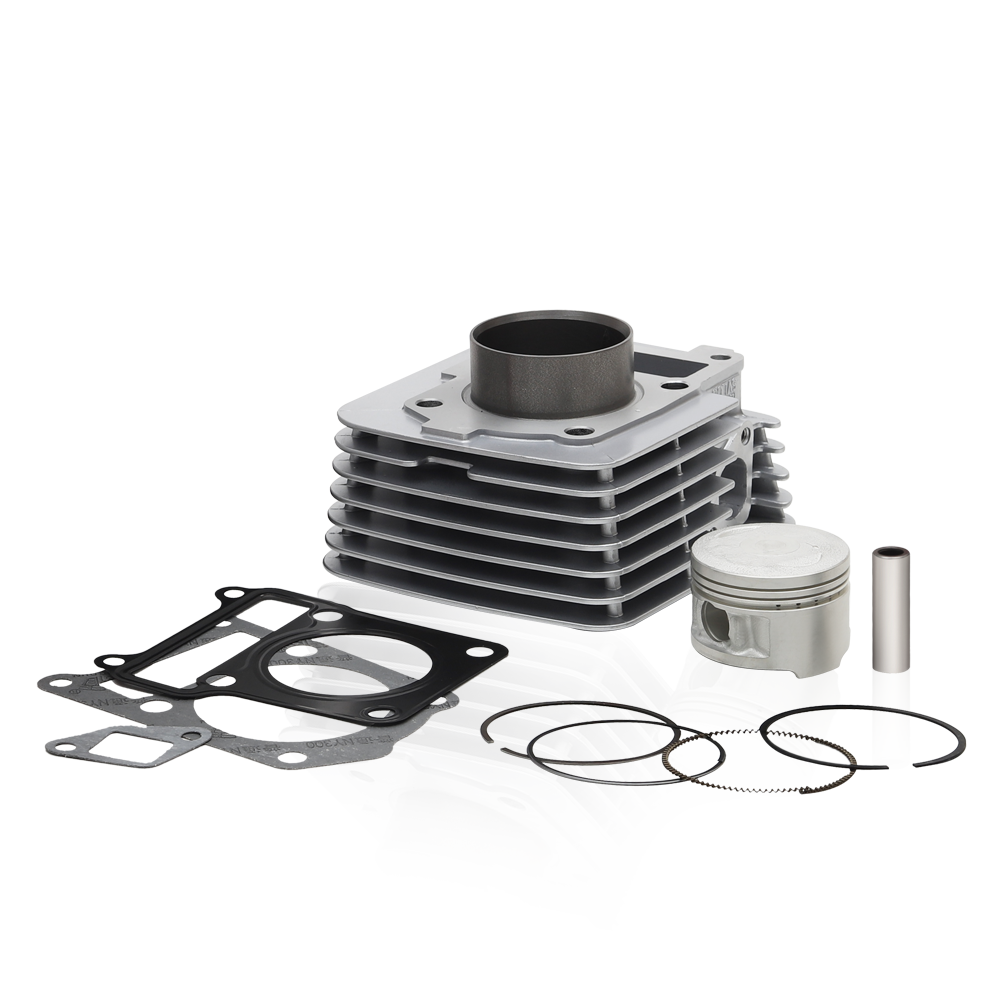

Our finesse begins with quality of our raw material and for piston kits; we utilize a superior AC8A aluminium material. Each of the following components of the kit is manufactured with high temperature resistance materials and is given the international quality

| Parameter |

Details |

At RITSUKA |

Chinese Product |

RITSUKA Advantage |

| BOP (Bought Out Parts) |

Piston Rings |

Inhouse |

BOP |

More the BOP’s higher are the chances of Rejection |

| Piston Pin |

Inhouse |

BOP |

| C Clips |

BOP |

BOP |

| Raw Material |

Piston |

High grade AC8A with copper content of 1.65% |

Substandard ADC12 with copper content of 0.5-0.8% which is below international standards |

We use fresh raw material composition engineered to reduce ductility and corrosion resistance. More ductility,i.e. =1%, leads to versatility and higher performance at lower cost |

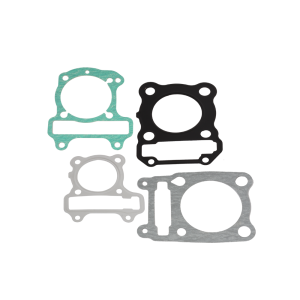

| Rings |

High Grade Rings Material

- Compression Ring – DH 30 Nodular cast iron

- Wiper Ring – (DQ20) STEEL

- Oil Ring – (DS45) STEEL

|

Normal Steel rings |

- Lightweight & structural material

- With precise specifications from high grade grey iron castings. Derived from OEM factory name ATG

|

| Piston Pin |

High Grade (20CrMo) Steel |

Low grade Steel |

RITSUKA products have high Resistant to corrosion |

Manufacturing

We focus on each step of manufacturing, right from technology to finishing. See how to outperform competition on the every of the manufacturing process

| Parameter |

Details |

At RITSUKA |

Chinese Product |

RITSUKA Advantage |

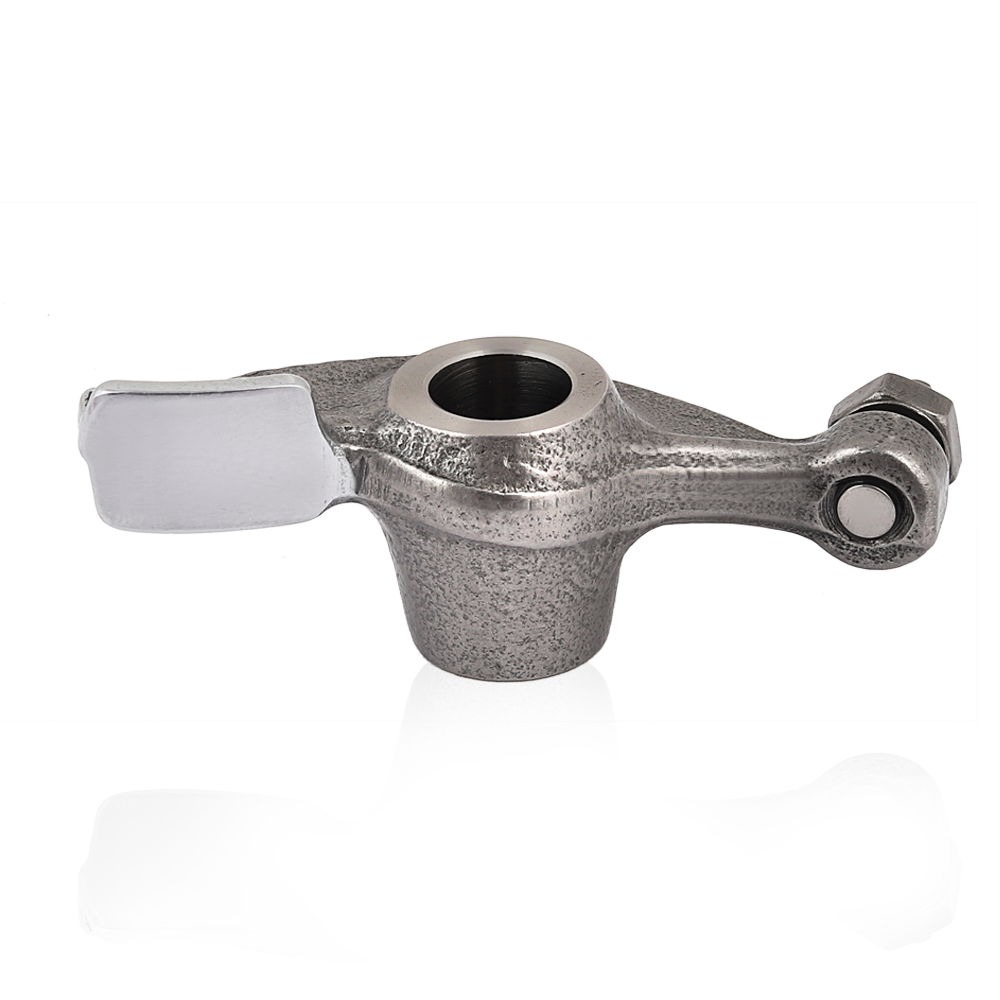

| Manufacturing |

Production Technology |

Fully Automated CNC machines with a capacity of 4 Pistons per minute |

Semi-Automated CNC or Lathe machines |

By using fully automated CNC machines, RITSUKA offers min Tolerance level products with negligible rejection at final stage |

| Vertical Milling Centre |

Fully Automatic VMC (Vertical milling centre) |

VMC not available with most of the factories |

Product is manufactured using VMC for precise Piston pin Bore and oil slots. These machines are only available with OEM manufacturers |

| Heat Treatment |

350-degree Heat treatment |

Max 250-degree Heat treatment |

1. We Ensure increase in hardness and obtain maximum strength and durability Maintain Brinell Hardness range of ? |

| Electroplating |

Automatic Plating shop with different finish available 1. Graphite finish 2. Oxidation 3. Tin finish |

Semi-Automatic / Manual plating facility |

1. We offer plating thickness of 0.6-0.8 micron 2. Protection from hot spots 3. Aids in flame propagation 4. Friction-side coatings to maintain radial tension in the rings 5. High longevity of pistons |

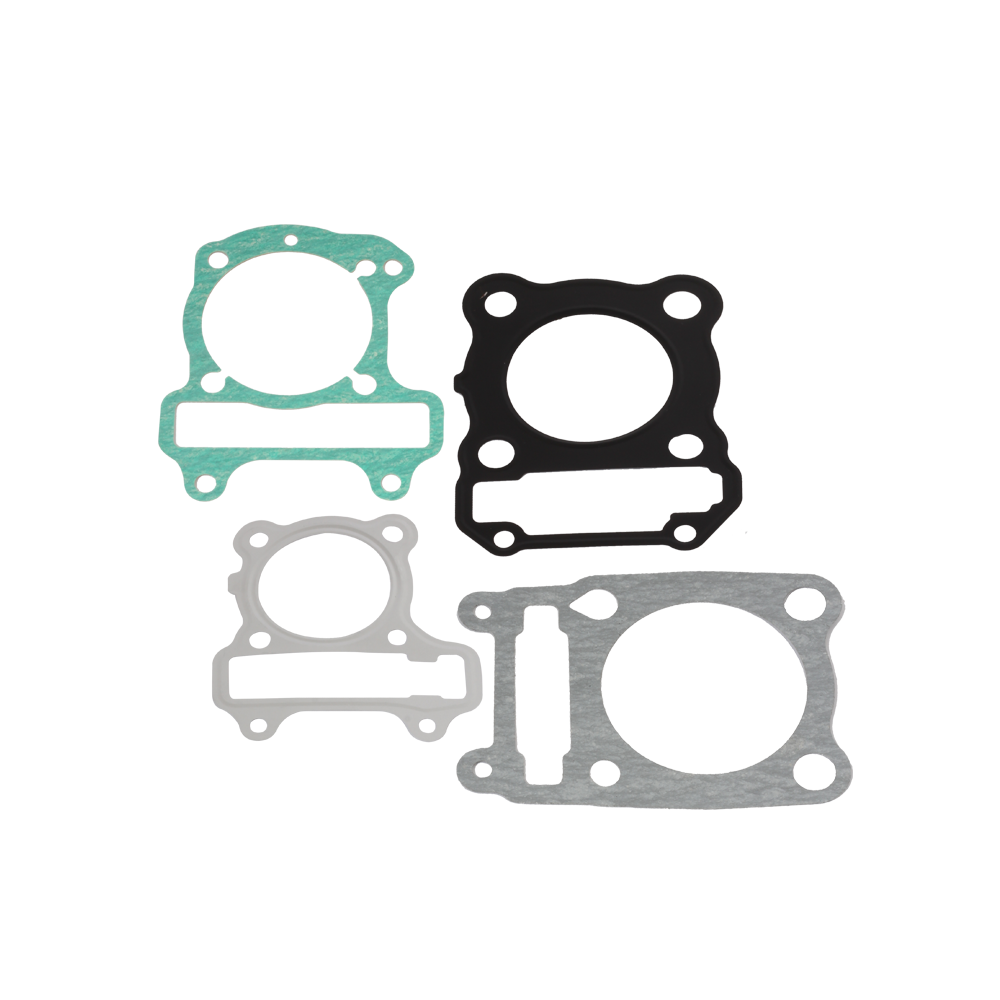

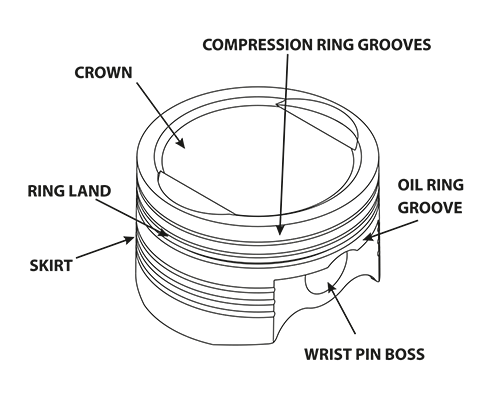

We manufacture and market a wide array of engineered pistons, piston pins, piston rings and circlips for the automotive markets.Extremely skilled 160 team members manage our modern R&D centre,which consists of three different departments: technical, development and mould making department. We produce complex cylindrical shaped and special shaped pin holes. Using the advanced mould processing equipment, we manufacture all kinds of casting, die-casting and forging die moulds with short production cycle, high production efficiency and stable quality. We offer graphite coating, tin plating and oxidation applied to piston skirts that act as a ‘self-clearing’ buffer between pistons and cylinder bores. As the pistons cycle, the coating wears in and fills incidental cylinder skirt/bore clearances. This creates an oil film layer for improved piston durability and engine output. For tins, the plating is relatively thick, giving tight tolerances and durability apart from the perfect exterior; this quality lining lends benefits to many more aspects. A coating offers reliable lasting protection on high performance applications. This coating is popular on most of the motorcycle builds. An excellent coating can protect this vital part and allows better combustion, less heat and friction, and valuable part protection.

In piston kit, we offer different types of finish – tin finish, regular shine finish and graphite coating.Apart from giving the spare part, the perfect appearance, a good finishing helps to create a smoother surface for higher overall functioning of a motorcycle engine.