Raw Material

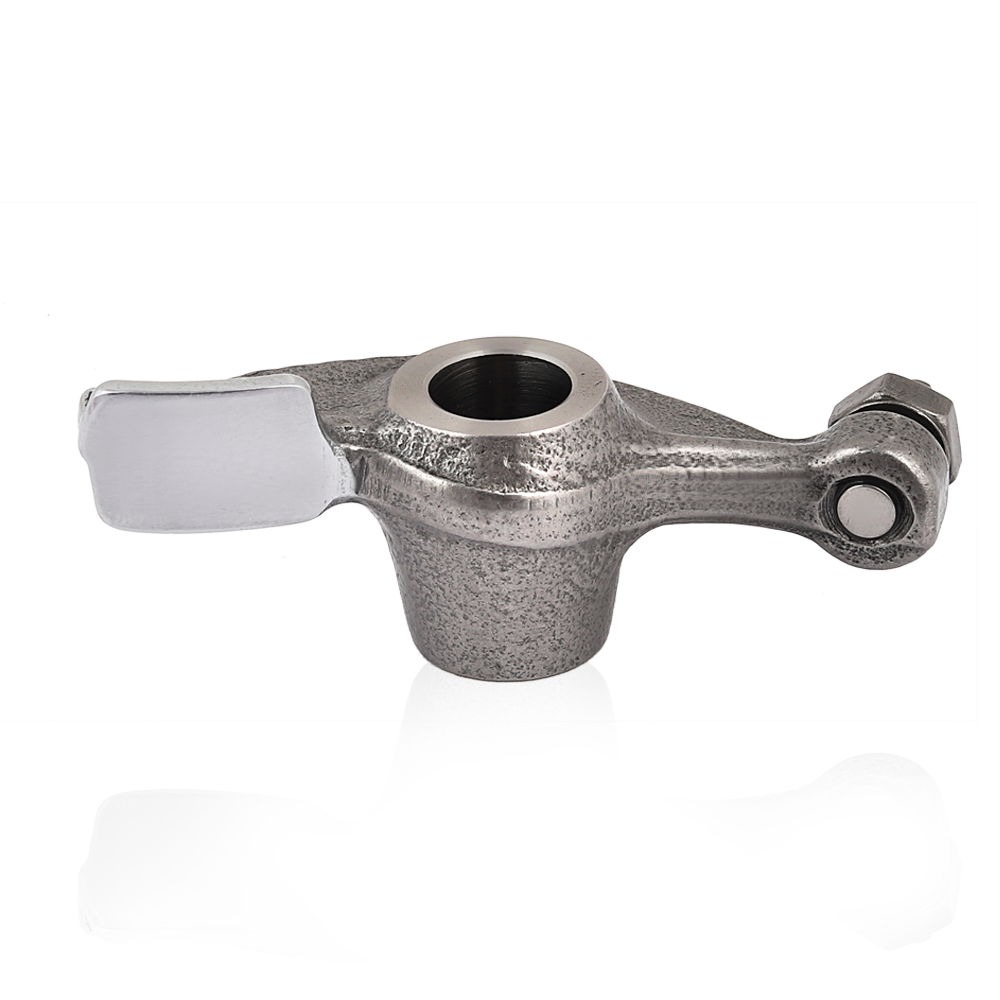

Our product is made from carbon steels by forging and casting process. Correct hardness and heat treatment cycle with accurately machined parameters ensures trouble-free performance of the product which is ensured by us. Rocker shafts of various types are made from alloy steels. Below is a comparison on how we select raw materials for the product.

| Parameter |

Details |

At RITSUKA |

Chinese Product |

RITSUKA Advantage |

| BOP (Bought Out Parts) |

Bearing |

BOP |

BOP |

We provide bearings from Taiwan maintaining OEM standards |

| Raw Material |

Body |

20CrMo Steel grade Raw Material |

Substandard Steel Grade Raw Material |

High Strength & High Yield, High Temperature resistant |

| Bearing |

Taiwan Quality Bearing |

Chinese Bearing |

Our product offers exceptional mechanical properties like durability, comfort and longevity along with safe ride. |

Manufacturing

With backward integration, we are capable of manufacturing rocker arm right from design and development stage to manufacture and supply the finished machined product all under one roof and supply to various customers all over the globe. Our comprehensive PPAP capabilities lend us our edge. Our state-of-the-art full gage room comes with dedicated CMM fixtures, air guages, dial bores, electronic bore gauges, etc. Each job has its own gauge box for quick and organized job launches. We also utilize gauge track as our gauge calibration tracking system. These excellent resources and thorough manufacturing result in superior rocker arm.

| Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| Manufacturing |

Machining |

CNC machining centre |

CNC machining centre Machines |

By using fully automated CNC machines, we offer min. Tolerance level products with negligible rejection at final stage. |

| Design centre, Tool room and R&D facilities |

In-house Design centre, tool room and R&D centre |

Not available with normal chinese factories |

We have an extra ordinary aptitude in developing customized formulations for steel products. For moulded products, we have in-house tool room with integrated facilities for mould design and mould manufacturing enabling quick lead time to customers |

| Moulding |

Automated moulding process |

Manual Moulding process |

Automated moulding results in Relatively poor wear under heavy duty conditions and at higher friction levels |

| Heat Treatment |

Inhouse Heat treatment process |

Outsourced in most of the factories |

Grain alignment to give better raw material strength and to reduce internal stress |

Rocker arms manufactured by us is available in one type of finish:

Original Steel

Finishing is an imperative stage of the entire manufacturing process as this controls exhaust scavenging potential, in taking air command and translating camshaft movement into valve actuation.